Waterjet Cutting

On the Cutting Edge. Literally.

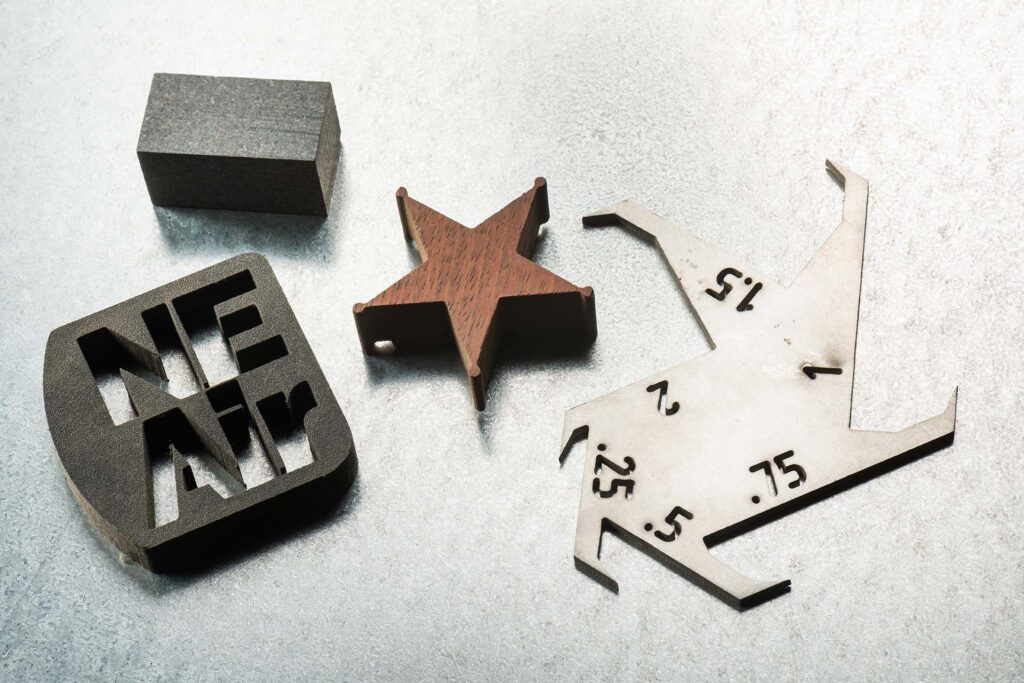

Our revolutionary in-house waterjet cutting equipment allows us to cut a wide variety of materials into virtually any shape—with a high level of accuracy and cost-effectiveness. This capability provides us with more agility to provide customized solutions for our clients’ mechanical system needs and the ability to provide custom fabrication services for a wide range of additional industries.

The Advantages of Waterjet Cutting

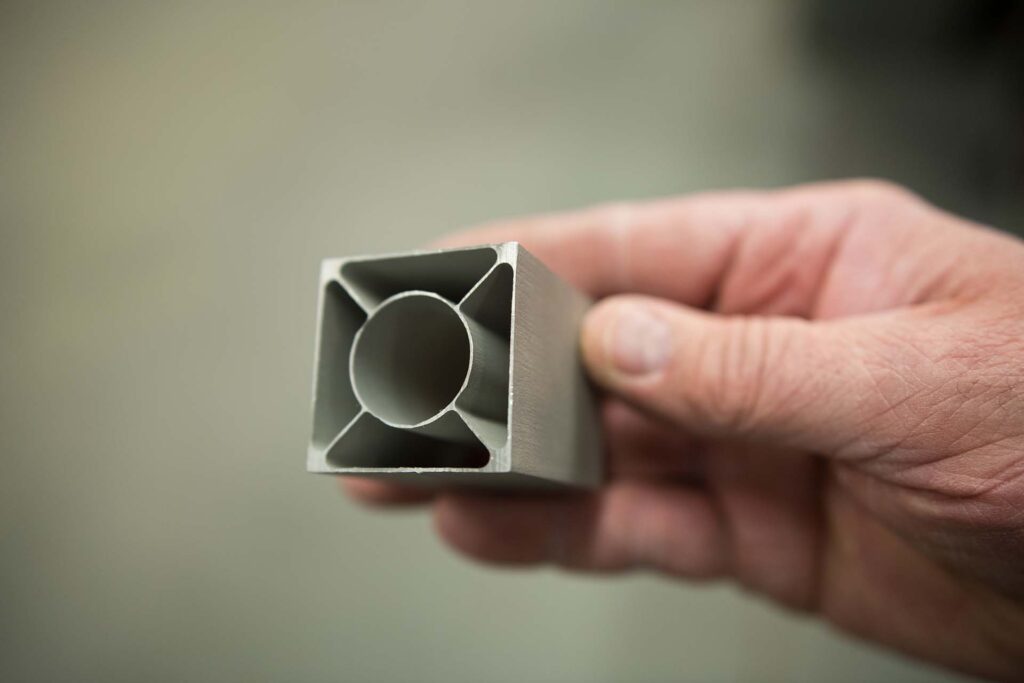

Waterjet cutting has several advantages that set it apart from traditional technologies in cutting and fabrication. This motion-operated technology can cut complex shapes from a multitude of materials and thicknesses, up to six inches. By using high-pressure water and garnet to cut the material away, the “cold cutting” process eliminates warping and distortion caused by chemical or heat processes. This ability to cut intricate parts with high accuracy and precision makes it an effective tool for HVAC systems and custom fabrication in specific industries, like medical, food production, pharmaceuticals, and aerospace—where precision is key.

Our waterjet cutting capabilities allow us to stand out from the competition. Our comprehensive services ensure that we begin every mechanical system or custom fabrication project with accurate parts, leveraging advanced technology to deliver top quality results. Complemented by our extensive shearing, bending, and welding capabilities, we can provide top quality results to diverse industries.

Customer Benefits

Using state-of-the-art waterjet cutting technology in our operations allows for unparalleled versatility, accuracy, and precision to our cutting and fabricating capabilities. With the ability to provide highly accurate custom fabrication in-house, we can provide custom solutions to our customer’s needs with speed, efficiency, and cost-effectiveness—all of which are not possible when sub-contracting the fabrication work to a third party. With more than 100 years of combined fabrication experience, this capability allows us to engage with our customers directly for more possibilities and better customized solutions.

Our Investment in Quality & Precision

With recent upgrades to our waterjet cutting capabilities, our fabrication shop is equipped with the latest and most state-of-the-art technology in the industry. New England Air Systems employs the Mach 500 waterjet series to meet our industry’s most demanding needs with precision, versatility, and performance. The Mach 500 is able to cut a wide range of materials all while maintaining tight tolerances on two-dimensional parts. Its additional cutting-edge features allow for easy programming and customization, making evolving project requirements more flexible. With its effectiveness and reliability, utilizing the Mach 500 technology allows us to provide tailormade solutions for our customers to achieve superior quality and increase productivity.

Interested in learning more about our Waterjet Cutting services?

We are here to answer any questions you may have about our Waterjet Cutting work.

Please use the link below to get in touch.