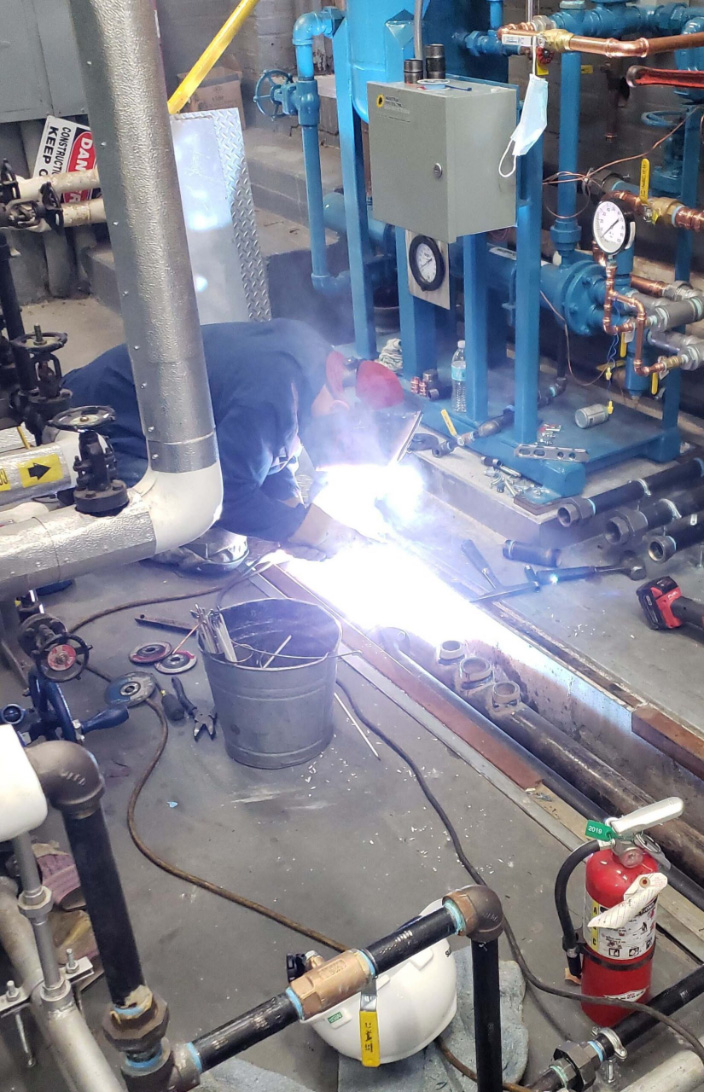

Welding

Linking Your Mechanical System Together.

Our team of welders deliver a full range of industrial pipe welding and custom fabrication. Our extensive piping capabilities range from 1/4-inch to 12” diameter and larger. Our certifications include various types of materials including carbon steel, stainless steel, copper, PVC, and more. Our welders have qualifications in both ferrous and non-ferrous metals for both pipe and plate that meets or exceeds industry standards. Our welders have qualifications in both ferrous and non-ferrous metals for both pipe and plate that meets or exceeds industry standards.

The Highest Quality in Welding

Our welders are trained, tested, and certified, to assure compliance with welding standards and code requirements. In addition, our welders are certified in ASME B.31.1 high pressure steam piping fabrication.

ASME B31.1 Power Piping Code requires training and certification in power piping codes and standards by the American Society of Mechanical Engineers (ASME). This certification code prescribes minimum requirements for the design, materials, fabrication, erection, test, and inspection of power and auxiliary service piping systems.

B31.1 covers boiler external piping for power boilers and high temperature, high pressure water boilers in which steam or vapor is generated at a pressure of more than 15 PSIG; and high temperature water is generated at pressures exceeding 160 PSIG and/or temperatures exceeding 250 degrees F.

See for Yourself

Our welders perform their craft in our shop or in the field.

Interested in learning more about our Welding services?

We are here to answer any questions you may have about our Welding work.

Please use the link below to get in touch.